Automation systems and services

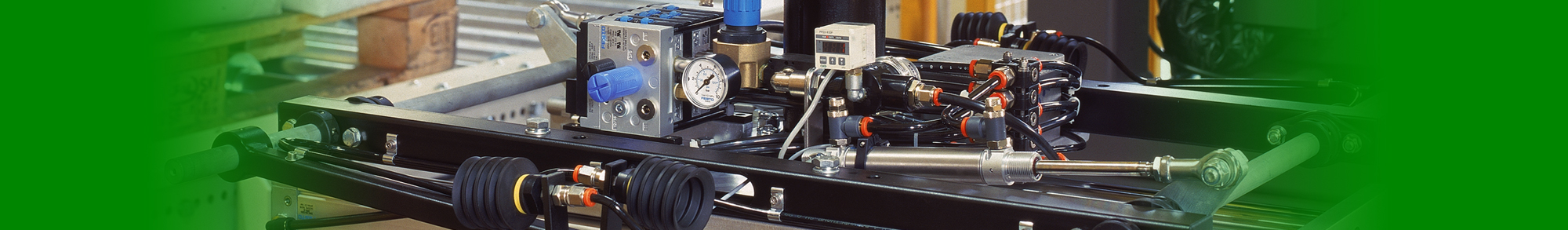

Modern packaging systems require a host of features that must be custom-installed to suit the customer’s specific needs. These features are an integral part of the production process, so it is impossible to classify them in a separate category. Here is a short description of the features that today’s modern technologies offer.

TRACKING - Systems for applying bar code labels or directly printing bar codes on products and finished pallets, with subsequent reading. Management and tracking of the products in the warehouse, thanks to the use of new automatic guided vehicles that do not require permanent installation.

SUPERVISION - Systems for acquiring process data and displaying it in graphic form on industrial monitors, which are used to control complex production lines.

NETWORKS - Networks that allow communication among various devices such as PLCs, PCs, printers, bar code readers, etc.

REVAMPING - Our technical service department specialises in upgrading existing technologies and integrating them into the plant to create a unified, efficient packaging department

TRACKING - Systems for applying bar code labels or directly printing bar codes on products and finished pallets, with subsequent reading. Management and tracking of the products in the warehouse, thanks to the use of new automatic guided vehicles that do not require permanent installation.

SUPERVISION - Systems for acquiring process data and displaying it in graphic form on industrial monitors, which are used to control complex production lines.

NETWORKS - Networks that allow communication among various devices such as PLCs, PCs, printers, bar code readers, etc.

REVAMPING - Our technical service department specialises in upgrading existing technologies and integrating them into the plant to create a unified, efficient packaging department

TAG:

TAG: